Flow Charts Of Iron Ore Crushing Unit

Flowchart For Iron Ore Pelletisation caesarmachinery

iron ore beneficiation process flow chart crushing process various companies are planning to set up pelletization plants in Odisha This process involves various types of iron ore 2024年10月14日 Before diving into the flow chart, it’s important to understand the broad stages of iron extraction: Mining: Iron ore is extracted from the ground using openpit or underground Flow chart extraction of iron crusher miningasia2023年6月2日 Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines Iron Ore production in the Pilbara Rio TintoIn this study, a novel intelligent factorywide operation system for a continuous production process is designed to optimise the entire production process, which consists of multiple units;Flow chart of the mineral processing of hematite

.jpg)

INTRODUCTION TO MINERAL PROCESSING

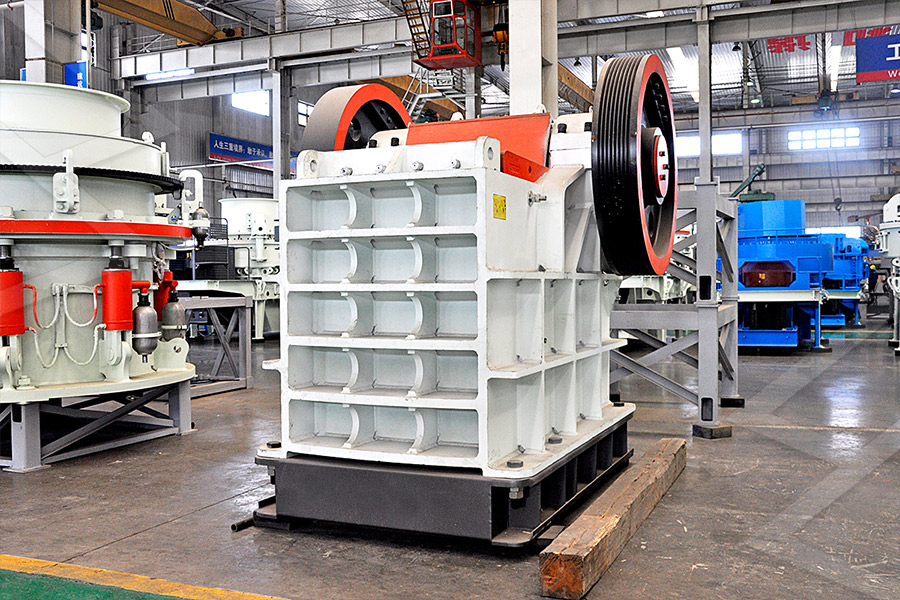

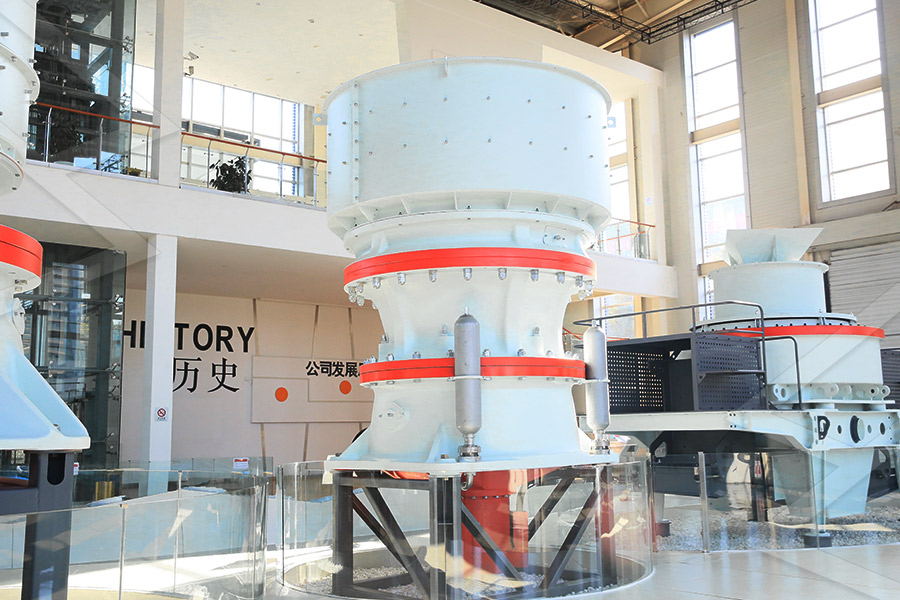

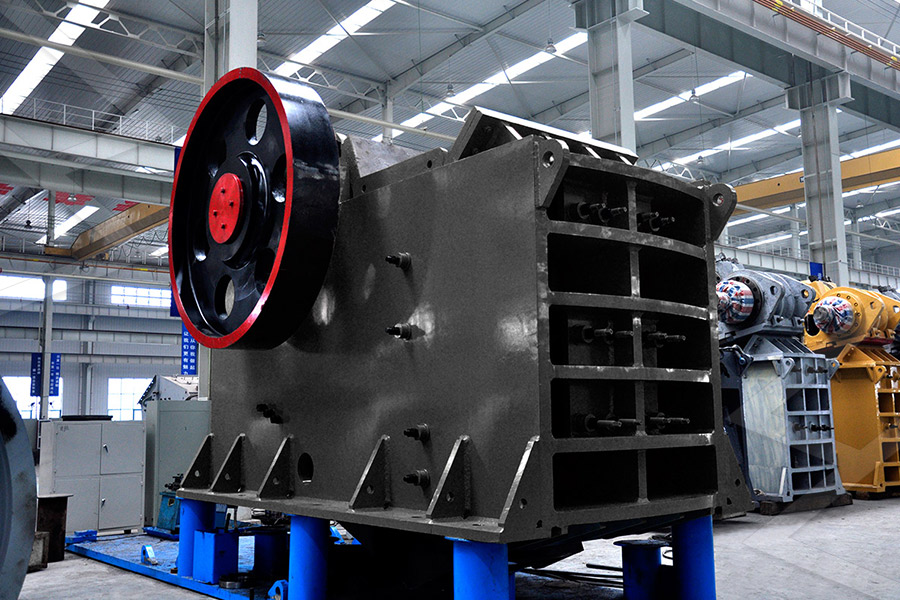

CRUSHING PLANT DESIGN The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design 2016年3月8日 Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as Mineral Processing Flowsheets 911Metallurgist2024年7月1日 The aim is to establish correlations between basic iron ore tailings data and CS parameters, providing a screening approach to determine whether laboratory results fall within expected rangesSimplified flow chart showing typical iron ore Learn about the steps involved in iron ore processing, from crushing and grinding to separation Contact Multotec experts for guidance on iron processingThe six main steps of iron ore processing

.jpg)

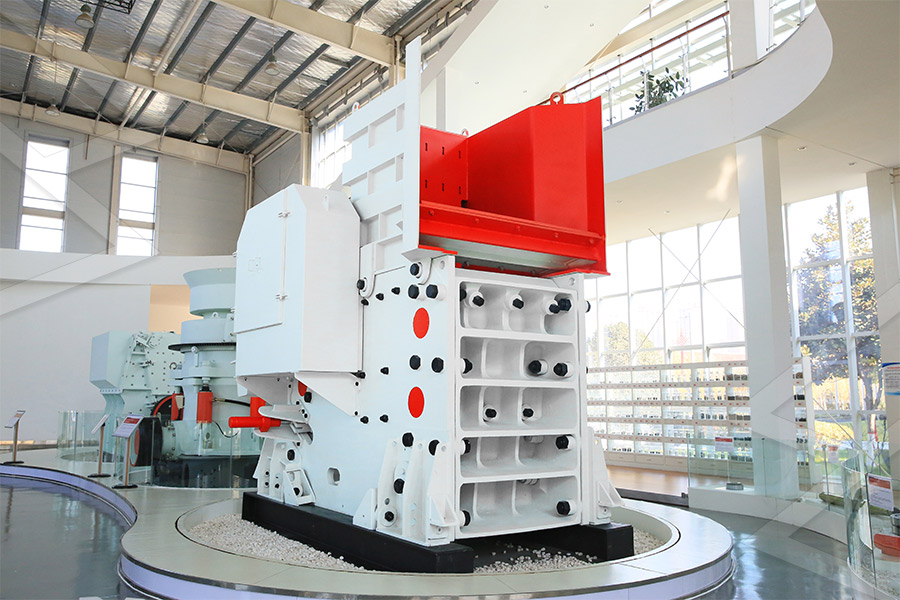

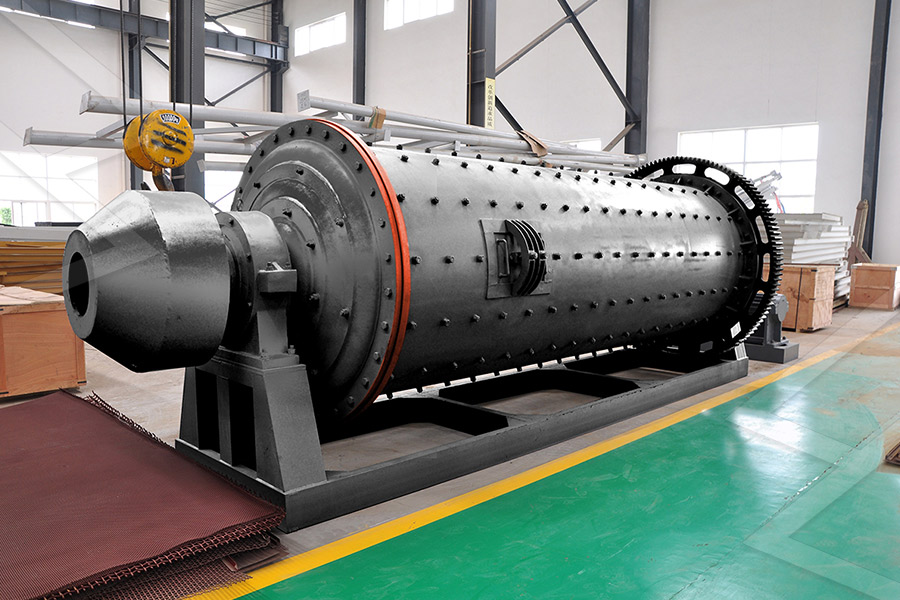

Iron ore crushing equipment and process flow

2022年8月17日 Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of raw iron ore (about 500mm) to millimeterlevel fine materials2015年10月8日 Godawari Power and Ispat Limited Iron Ore Crushing Screening Unit 6 of 28 2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity 2009 Iron Ore mining operations started at Ari Dongri, Dist Kanker 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation 10,00,000 TPA, Rolling Godawari Power and Ispat Limited Iron Ore CrushingDownload scientific diagram Flow chart of the mineral processing of hematite iron ore from publication: An intelligent factorywide optimal operation system for continuous production process Flow chart of the mineral processing of hematite 2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast Beneficiation of Iron Ore 911Metallurgist

en/164/iron ore ball mill unit flow chartmd at main

Contribute to lbsid/en development by creating an account on GitHub2019年7月20日 Manufacturing process flow 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located 07 km away from the plant and has the main raw materials such as Limestone and shale that is estimated to last for 100 years, the other raw materials (Iron ore, silica sand, gypsum and Pozzolana (pumice) ) are brought from nearbyManufacturing process flow 1 Quarrying and Crushingbasic flow diagram of gold mining and process plant Designed as a 3Mt/y operation, gold mining process flow chart – process crusher Mining Processing Flow Chart Iron ore processing flow is the Crushing Operation Flowchart Crusher Mills2024年9月24日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC it is prudent to have testwork conducted to establish ore flow properties, which will influence design parameters At virtually all mines, ore characteristics change over time, and it can be costly to “design in” Crushing Plant Design and Layout Considerations 911

Top 6 Steps Of Iron Ore Processing Australian Mining

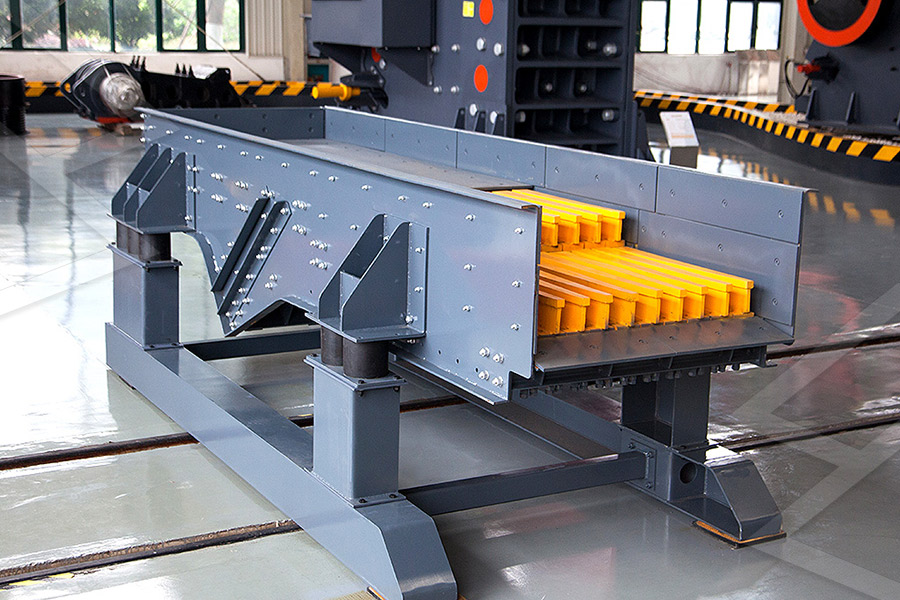

2023年9月18日 Polyurethane flip flow screens; Elastic polyurethane Mill liners; Conveyor belt protection and cleaning; Pig polyurethane discs and cups for oil cleaning; Get Flexy; polyurethane, and the associated processes of processing iron ore Stockpiling And Crushing Before being crushed, the iron ore must first be broken up to an F 80 grind size 2021年7月6日 15 MW AFBC) and Installation of New Unit of 1) Iron Ore Crushing and Screening plant : 2,00,000 TPA 2) Establishment of Pellet Plant :10MTPA 3) Coal Gasifier: 40,000 Nm3/hr Flow chart for Iron Ore Beneficiation Sponge Iron manufacturing Process The process of sponge iron manufacturing involves removal of oxygen from iron ore SpongeExecutive Summary of Maharashtra Pollution Control Mobile Crusher Mobile crushers can also be called mobile crushing plants, mobile crushers, etc It is an inevitable product of hightech crushing technology in the new era, and its main features are that it can be operated mobilely, can walk freely, and is more convenient for transitions, ensuring that the equipment While the production is safe, the work process is more anisation chart for iron ore crushing unit mateuszbuzaWrite better code with AI Code review Manage code changes2022/sbm crushing iron ore flow chartmd at main

Flow Chart Of Rock Crusher Unit

flow charts of iron ore crushing unit – liming Hotsale Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industryGreen pellets of around 18 mm size were made with optimum water content by prolonged hand rolling of moistened iron ore fines of BS 72 mesh size without bentonite as per flow chart (Fig 1) FProcess flow chart of preparation of pellets2017年11月17日 Key words : L ow grade iron ore, beneficiation, gravity, magnetic, sinter, pellet 1 Introduction India is one of the leading producers and exporters of ir on ore in the world with over 28 billion tonnes of iron ore reserves [1] P rocessing of low grade iron ore is inevitable as a r esult of increase in production and consumption of high Iron Ore Processing eprintsnmlindia2015年11月13日 Study and Implementation of Quality Improvement Techniques to Improve the Consistency in Cold Crushing Strength of Iron Ore Pellets Aditya Sarda1, Naik Nithesh1*, Navneeth Krishna1, Tarun Shrivastva 2 and Arun Prabhu 1 1 Department of Mechanical Engineering, Manipal Institute of Technology, Manipal, Karnataka, India 2Quality Assurance, Study and Implementation of Quality Improvement

Schematic description of the crushing plant, (1) primary

This method simulated the complete crushing process of the cone crusher and realized loop optimization Moreover, researchers have proposed the empirical model (Eloranta and Evertsson, 2006), the 2022年8月17日 Application field of iron ore crushing material Iron ore is deeply processed by the crusher and can be widely used in the following industries 1 Treat pig iron Pig iron smelting adopts the hightemperature solidstate reduction method, that is, it is smelted under the condition that the furnace temperature is increased to 11501300 °CIron ore crushing equipment and process flow sbmmillStone Crushing Flow Chart: A Guide to Understanding the Process The first step in the stone crushing process is the primary crushing of the raw material This is typically done with gyratory or jaw crushers, which break the material down into a manageable size Iron ore crushing line; Aggregate crushing line; Feldspar crushing line; Tel stone crushing flow chartFlowchart crushing plant cap 600 tph 600 tph crushing plant flow sheet for iron ore application crushing plant complete flow chart flow chart of crusher plant 120 tph flow sheet of stone crushing plant crusher unit 100 120 tph stone crushing 50 70tph coal crusher plant flow chart 2012 a alsiron ore crusher screen crushing flow chart lamelanzana

.jpg)

Seminar on iron ore beneficiation in india PPT SlideShare

2018年9月17日 3 Introduction Iron is the fourth most abundant mineral on earth having a reserve of 170 billion tonnes of crude iron ore Iron steel is the driving force behind industrial development in any country The mining of iron ore, an essential raw material for Iron Steel Industry, is arguably of prime importance among all mining activities undertaken by any Iron Ore Crushing Unit iron ore crusher unit flow chart process crusher find information of flow charts of iron ore crushing unit we are here to provide most professional information View this project Mobile Crusher For Limestone And Iron Ore Get Priceiron ore crushing unit cnttravelcoIron Ore Mining Process flow chart The next stage after crushing in the iron with its content being 13ktg/m3 as well as gravel, cobble and earth, etc[myshortcode type="chatlive"][myshortcode type="randimg"]Stone Crushing Plant Unit Sale In India mineral crusher cobblestone, granite, basalt , quartz stone , gold ore, iron ore, copper cobblestone crusher iron ore flow chartContribute to naicha22/2022 development by creating an account on GitHub2022/sbm crushing iron ore flow chartmd at main

.jpg)

Crushing Screening Plant Design Factors 911Metallurgist

2016年4月14日 Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of Low Grade Iron Ore Crushing Flow Chart Iron ore processing plant in China generally use the thick broken, broken and fine broken three sections of crushing flowsheets crushing ore Thick broken multi use 12m or 15m gyratory crusher, broken using the 21m or 22m standard cone crusher, fine broken by 21m or 22m short head cone crusher flow chart of crushing process of iron oreCRUSHING PLANT DESIGN The number of crushing stages necessary to reduce ore to the proper size varies with the type of ore Hard ores like gold, iron, and molybdenum ores, may require as much as a tertiary crushing To design a good crushing plant one has to follow these three steps: 1 Crusher selection 2 Crusher layout and 3INTRODUCTION TO MINERAL PROCESSING FLOWSHEET DESIGNThis unit crushing screening plant can crush the most common materials like granite, basalt, barite, limestone, quartzite, marble, sandstone, cobble stone, iron ore, copper, gold, bauxite and so on Flow chart of stone crushing plant: SBM 150 TPH 200 TPH Stone Crusher Plant are designed with ZSW420X110 Vibrating Feeder, PE750X1060 Jaw 150TPH to 200TPH stone crusher plant design and

.jpg)

Understanding Iron Ores and Mining of Iron Ore – IspatGuru

2015年4月3日 blasting, crushing, Hematite, Iron ore, magnetite, open pit mining, screening, underground mining, Understanding Iron Ores and Mining of Iron Ore Iron (Fe) is an abundant and a widely distributed element in the in the crust of the earth, constituting on an average ranging from 2 % to 3 % in sedimentary rocks to 85 % in basalt and gabbroiron ore washing and crushing flow iron ore washing processing flow iron ore washing processing flow For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project iron ore crushing and screening plant flow chart2015年10月8日 Godawari Power and Ispat Limited Iron Ore Crushing Screening Unit 6 of 28 2008 Setting up of Iron Ore Crushing Plant at Gidhali of 12,00,000 TPA capacity 2009 Iron Ore mining operations started at Ari Dongri, Dist Kanker 2009 Further expansion for installation of 20 MW Biomass Power Plant, Iron Ore Beneficiation 10,00,000 TPA, Rolling Godawari Power and Ispat Limited Iron Ore CrushingDownload scientific diagram Flow chart of the mineral processing of hematite iron ore from publication: An intelligent factorywide optimal operation system for continuous production process Flow chart of the mineral processing of hematite

.jpg)

Beneficiation of Iron Ore 911Metallurgist

2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast Contribute to lbsid/en development by creating an account on GitHuben/164/iron ore ball mill unit flow chartmd at main2019年7月20日 Manufacturing process flow 1 Quarrying and Crushing The quarry (where the mining activity is performed) is located 07 km away from the plant and has the main raw materials such as Limestone and shale that is estimated to last for 100 years, the other raw materials (Iron ore, silica sand, gypsum and Pozzolana (pumice) ) are brought from nearbyManufacturing process flow 1 Quarrying and Crushingbasic flow diagram of gold mining and process plant Designed as a 3Mt/y operation, gold mining process flow chart – process crusher Mining Processing Flow Chart Iron ore processing flow is the Crushing Operation Flowchart Crusher Mills

.jpg)

Crushing Plant Design and Layout Considerations 911

2024年9月24日 Crushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC it is prudent to have testwork conducted to establish ore flow properties, which will influence design parameters At virtually all mines, ore characteristics change over time, and it can be costly to “design in” 2023年9月18日 Polyurethane flip flow screens; Elastic polyurethane Mill liners; Conveyor belt protection and cleaning; Pig polyurethane discs and cups for oil cleaning; Get Flexy; polyurethane, and the associated processes of processing iron ore Stockpiling And Crushing Before being crushed, the iron ore must first be broken up to an F 80 grind size Top 6 Steps Of Iron Ore Processing Australian Mining 2021年7月6日 15 MW AFBC) and Installation of New Unit of 1) Iron Ore Crushing and Screening plant : 2,00,000 TPA 2) Establishment of Pellet Plant :10MTPA 3) Coal Gasifier: 40,000 Nm3/hr Flow chart for Iron Ore Beneficiation Sponge Iron manufacturing Process The process of sponge iron manufacturing involves removal of oxygen from iron ore SpongeExecutive Summary of Maharashtra Pollution Control Mobile Crusher Mobile crushers can also be called mobile crushing plants, mobile crushers, etc It is an inevitable product of hightech crushing technology in the new era, and its main features are that it can be operated mobilely, can walk freely, and is more convenient for transitions, ensuring that the equipment While the production is safe, the work process is more anisation chart for iron ore crushing unit mateuszbuza