Aggregate Mining Dust Suppression Histroy Of Bowl Mill In Power Plant

.jpg)

Particle aggregation and the grinding limit in high energy ball mill

Two types of dust aggregates are formed in a planetary ball mill Kink of monomers “stickiness” in unstable aggregates indicates a grinding limit Plastic deformation mode leads to stable 2022年5月24日 This paper discusses qualitative methods for preventing dust including design of a wet centrifugal dust collector Since wet dust suppression system uses optimum amount of water forDUST MANAGEMENT AT COAL HANDLING Fugitive dusting can be greatly reduced and controlled with a properly designed and applied dust suppression system Dust Control Limitations in the Aggregates Industry Dustreduction methods have included using sprinklers or hoses to Dust Suppression Methods for the Aggregate 2021年8月1日 This paper introduced the research progress of dust and air separation mechanism and multiphase flow simulation technology in dust removal and suppression, as Research Status of Dust Reduction Technology in Coal

.jpg)

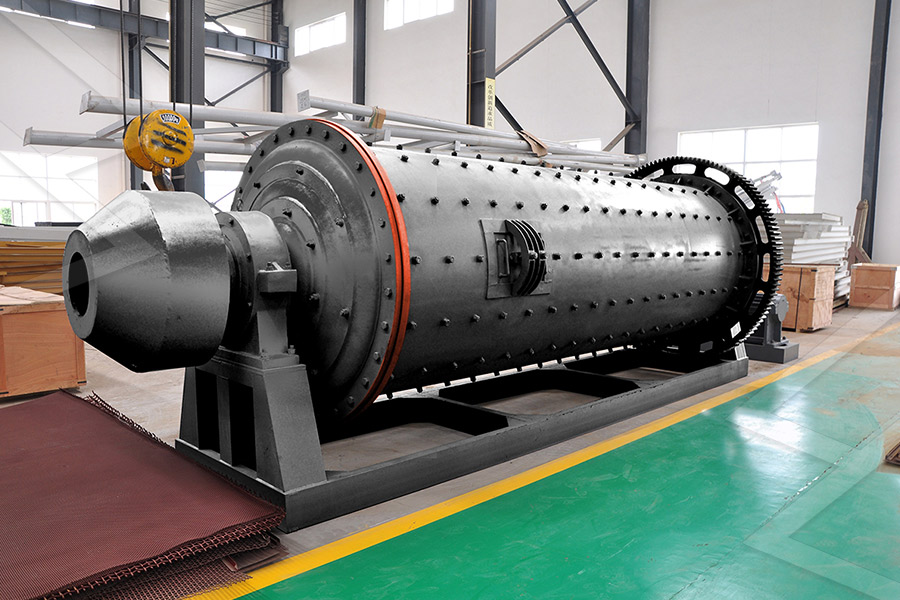

Bowl Mill Coal Pulverizer COAL HANDLING

2023年12月14日 Coal Pulverizer are designed to reduce the size of the incoming raw coal to a fineness that will result in good furnace performance The grinding surface in the pulverizer resembles a shallow dish or bowl Therefore 2023年4月13日 They outlined some of the strategies that have been developed for mine dust control from the aspects of ventilation dust removal, spray dust reduction, chemical dust suppression, foam dust suppression, and dust Advanced Technologies on Mine Dust For over a decade, BossTek has served the aggregate industry by providing effective dust suppression solutions for pits and quarries of all sizes The DustBoss® line of products utilizes atomized mist technology to trap dust Dust Suppression for Aggregate BossTek2020年11月21日 This paper deals with a smart dry fog dust suppression system which has been developed for effectively controlling dust emission from mining and mineral processing Intelligent dry fog dust suppression system: an efficient

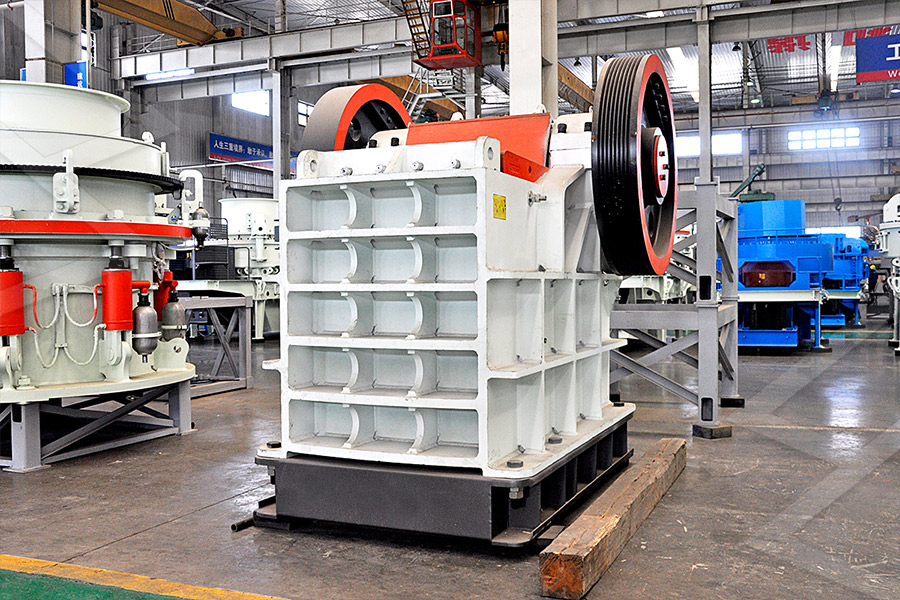

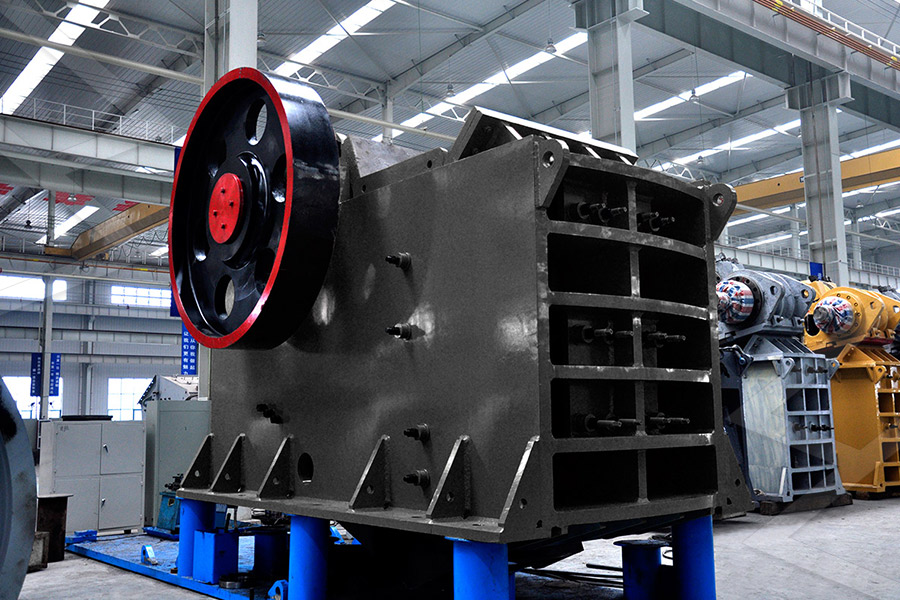

Pulveriser in Thermal Power Plant Bowl Mill

2021年8月5日 The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a predetermined size in order to increase the surface area of the coalVertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics2023年9月27日 1 Bowl mills 2 Venture multiport outlet and mill discharge valveassembly 12 BOWL MILLS 121 INTRODUCTION The bowl mill is medium speed ring roll mill, with no metal to metal contact between Design and Modify of Mill Discharge Valve Using in

.jpg)

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill

pulverizer 1003 XRP Bowl Mills shown at Figure 1, for guaranteed performance at a 500 MW capacity NTPC thermal power plant The cross section of the coal bowl mill is shown in Figure 2 The study was conducted to assess the effective performance of the pulverizers of this 500 MW boiler unit for its optimum output in terms of the fineness of2018年6月7日 • Smoldering coal inside an idle mill can evolve into a big problem when the mill is started, agitating these accumulation combined with a high air to fuel ratio environment • PRB is one of the most difficult coals with respect to mill fires and explosions • Mill internal temperatures are generally high enough somewhere to ignite any type ofMill Inerting and Pulverizer/Mill Explosion Mitigation2022年7月1日 The dust suppression efficiency of hybrid ventilation system depends on the dust control effect of ventilation system and dust removal effect of dust removal device The optimal hybrid ventilation system is required to ensure that dust particles enter the exhaust air duct and are eventually removed by the dust removal deviceReview and prospect the development of dust suppression Gulin Least News crusher parts suppliers in ireland » The More » quarry equipment for sale brisbane » used mining equipment and for sale and usa or europe and used jaw crusher » types of bowl mill in power plant » significant economic impact associated with coal mining » use of autoclaved aerated concrete block by rajdeep chowdhury Contact Us Tel: 8621types of bowl mill in power plant – Grinding Mill China

.jpg)

Research Status of Dust Reduction Technology in Coal

2021年8月1日 Aiming at the dust control of coal handling system in thermal power plant, the research status of dust reduction related theory and technology was summarized This paper introduced the research progress of dust and air separation mechanism and multiphase flow simulation technology in dust removal and suppression, as well as the features and 2009年12月14日 The dust from either type of storage can be offloaded via a road tanker or passed through a dustconditioning mixer, where approximately 10–20% of water is added to turn the dry dust into a waterbased mix that can be discharged and handled with minimum dust nuisance If the 0–5mm aggregate can accept the predominantly –63 micron Dust Control In The Aggregates Industry AggNetContribute to dihog/sbm development by creating an account on GitHubsbm/sbm bowl mill in power plantmd at main dihog/sbm2023年5月1日 A variety of dust control methods are often applied in coal mines, among which the application of wet scrubbers has proven to be an efficient technology for the removal of dust in airstreams Optimization study on the application of

.jpg)

crusher/sbm process of thermal power plant bowl millmd at

Contribute to yunan88/crusher development by creating an account on GitHub2018年11月26日 Different mining areas are exposed to different dust levels and to minimize the probability of occupational respiratory disease of coal miners, it is necessary to evaluate dust concentration in (PDF) Critical Review of Dust in the Mining Environment: A 2022年5月5日 Monitoring with the use of stateoftheart dust suppression methodologies; A field visit to collect operationcritical information; Development of a situation analysis of the crusher plant; Proposal of different dust suppression strategies; Dust measurements before and after operations have been developedHow do you control dust in a crushing plant?bowl mill in thermal power plant bowl mill in thermal power plant As a professional crushing and grinding equipments manufacturer, liming can supply you all kinds of machinery for you all over the world Burma operator manual for a raymond bowl mill for mine processing plant and stone power plant CE RAYMOND BOWL MILL FOR CERAYMOND BOWL MILL FOR THERMAL POWER PLANT Crusher Mills

.jpg)

power plant bowl mill specification – Grinding Mill China

2021年7月14日 bowl mill specifications Specifications: Holland Bowl Mill Bee’s Oil Darken your Quarrying Crusher Plant raymond bowl mill,barite Bowl and roller mill type MPS – Hitachi Power » Free online chat! hp 1103 bowl mill specification – Crusher South Africa Posts Related to hp 1103 bowl mill specification used raymond bowl mill Thermal Power Plants 2014年1月1日 In this study, the durability of paste backfill (CPB) made from sulphidic tailings, ordinary (OPC) and pozzolanic (PPC) Portland cements and alkali activated slag cements (AAS: LSSS; slag Factors affecting the performance of crushing plant operations2021年7月14日 Gulin Least News gold trommel washplant vme24 price » The More » coconut shell crusher machine usa » bowl mill in power plant » diesel mining compressor in gauteng » free ebooks on mining geology » deep mining or underground mining Contact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, China Postcode: bowl mill in power plant – Grinding Mill China2024年2月8日 Tramp metal that enters the grinding zone can create sparks and ignite the dust in the mill Sometimes even nonsparking tramp metals can contribute enough heat through friction to ignite the dust in a mill Whichever mechanism ignites the dust, the ignition can start a fire and potentially lead to an explosion and subsequent secondary explosionsReducing the risk of dust explosions in mills and size

crusher/sbm bowl mill in thermal power plant pdfmd at

Contribute to yunan88/crusher development by creating an account on GitHubDust suppression products keep dust under control in mining by neutralizing dust particles from becoming airborne Dust suppression products come in various forms, such as: Soil Stabilizers; Wetting Agents; Dust Control Sprays and Mists; Foam Suppressants; These products work by coating dust particles, making them heavier so they can't become The Role of Dust Suppression Products in Mining Operations2024年1月18日 The automated and integrated dust suppression and control spray system for haul roads in mines and dust emitting plants sprays water automatically to address the dust source immediately Dust weather stations, Dust Control in Mines: Methods, Sources, 2019年8月1日 In thermal power plant each boiler uses pulverized coal as main fuel for combustion High performance bowl mills of bowl size 80" are used for pulverizing the coal to required fineness of about 70 Design and Modify of Mill Discharge Valve Using in Thermal Power Plant

.jpg)

Monitoring Model of Coal Mill in Power Plant Based on Big

In order to monitor the wear condition of grinding roller of coal mill in power plant and improve the reliability of production equipment, it is necessary to establish a state monitoring model with high accuracy and good prediction effect It has been shown that the power of coal mill can reflect the wear degree of grinding roller If the voltage and power factor of coal mill are constant 2024年12月16日 Power generation industry studies have shown that pulverized coal power plants are an area where improved equipment reliability is essential The Electric Research Institute (EPRI) has determined that 1% of plant availability is lost on average due to pulverizerrelated problemsCoal Pulverizer – Power Plant Pall Corporation2023年5月17日 Thermal power plants are very important to a country’s energy, and dust is a major threat to the safety of thermal power plants Over the past decade, dust explosion events of various degrees have emerged one after another, leading to serious respiratory disease, lung disease and even death Therefore, the prediction of dust situation in coal mining face is Dust concentration prediction model in thermal power plant 3 天之前 The Minerals Council South Africa established the Learning Hub in 2009 to encourage mining companies to learn from the pockets of excellence that exist in the i Home;; Online tools; Contact; ≡ Open menu Home; About us Foam Dust Suppression System N Murray (362 MB) Adoption of CBAT and CRTM H Morebodi Dust Mining Industry Occupational Safety Health MOSH

.jpg)

shibang/sbm bowl mill power plantmd at master

You've already forked shibang 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityVertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics2023年9月27日 1 Bowl mills 2 Venture multiport outlet and mill discharge valveassembly 12 BOWL MILLS 121 INTRODUCTION The bowl mill is medium speed ring roll mill, with no metal to metal contact between Design and Modify of Mill Discharge Valve Using in

A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill

pulverizer 1003 XRP Bowl Mills shown at Figure 1, for guaranteed performance at a 500 MW capacity NTPC thermal power plant The cross section of the coal bowl mill is shown in Figure 2 The study was conducted to assess the effective performance of the pulverizers of this 500 MW boiler unit for its optimum output in terms of the fineness of2018年6月7日 • Smoldering coal inside an idle mill can evolve into a big problem when the mill is started, agitating these accumulation combined with a high air to fuel ratio environment • PRB is one of the most difficult coals with respect to mill fires and explosions • Mill internal temperatures are generally high enough somewhere to ignite any type ofMill Inerting and Pulverizer/Mill Explosion Mitigation2022年7月1日 The dust suppression efficiency of hybrid ventilation system depends on the dust control effect of ventilation system and dust removal effect of dust removal device The optimal hybrid ventilation system is required to ensure that dust particles enter the exhaust air duct and are eventually removed by the dust removal deviceReview and prospect the development of dust suppression Gulin Least News crusher parts suppliers in ireland » The More » quarry equipment for sale brisbane » used mining equipment and for sale and usa or europe and used jaw crusher » types of bowl mill in power plant » significant economic impact associated with coal mining » use of autoclaved aerated concrete block by rajdeep chowdhury Contact Us Tel: 8621types of bowl mill in power plant – Grinding Mill China

.jpg)

Research Status of Dust Reduction Technology in Coal

2021年8月1日 Aiming at the dust control of coal handling system in thermal power plant, the research status of dust reduction related theory and technology was summarized This paper introduced the research progress of dust and air separation mechanism and multiphase flow simulation technology in dust removal and suppression, as well as the features and 2009年12月14日 The dust from either type of storage can be offloaded via a road tanker or passed through a dustconditioning mixer, where approximately 10–20% of water is added to turn the dry dust into a waterbased mix that can be discharged and handled with minimum dust nuisance If the 0–5mm aggregate can accept the predominantly –63 micron Dust Control In The Aggregates Industry AggNet